Brewery Automation

Whilst the true promise of AI and machine learning seem to keep being pushed to the horizon, there’s no doubt that we leave many things to machines now that would previously have been inconceivable. Cars can do 90% of the steering on a motorway, music tastes are garnered and extrapolated by Spotify, texts and appointments are dictated and we’re losing traditional jobs to artificial intelligence. Repetitive tasks are being taken from human hands and being put into the control of PLC’s, actuators and relays.

Which makes it perhaps slightly surprising that many of our brewers are still running up and down brewhouse steps opening and closing valves, turning on and tuning pumps and many other things that a decent PLC could do without barely a flick of its processor. As skilled brewers start to command the kind of salaries they deserve, the cost benefit of time-poor humans vs. ever alert computers becomes something worthy of review.

Philosophically too, our brewing industry seems to strive and survive on long hours, physical effort and lots of timers set on phones. One can certainly question whether paying someone $80k+++ a year to open and close valves is the best use of their time when all that hard fought experience should be focused on a higher plane, systems implementation and improvement, sensory evaluation, looking after complex multi-celled organisms (humans) and simple single-celled organisms (yeast).

Ideally then, we need to start thinking about letting the machines do they what they do best, the repetitive, the simple and the mundane; freeing our humans to do what they do best, create, improve, control and inspire.

Let’s take a look then at what automation actually means in a brewery.

Simple Control/ Manual Control

Set a temperature on your fermenter and a solenoid controls the flow of glycol to the tank. Do the same to your mash tun and a burner comes on. These are simple temperature controllers standard fare in almost all breweries nowadays. Everything else however, opening valves, controlling flows and flow rates are all done by human power.

Pro’s – cheap, reliable.

Con’s – full time brewer needed.

Use – up to 10hL.

Semi-automatic Control

Bit of a broad brush this one but at their heart, semi-automatic breweries have a touch screen, a simple PLC and actuated valves (open/close remotely with compressed air).

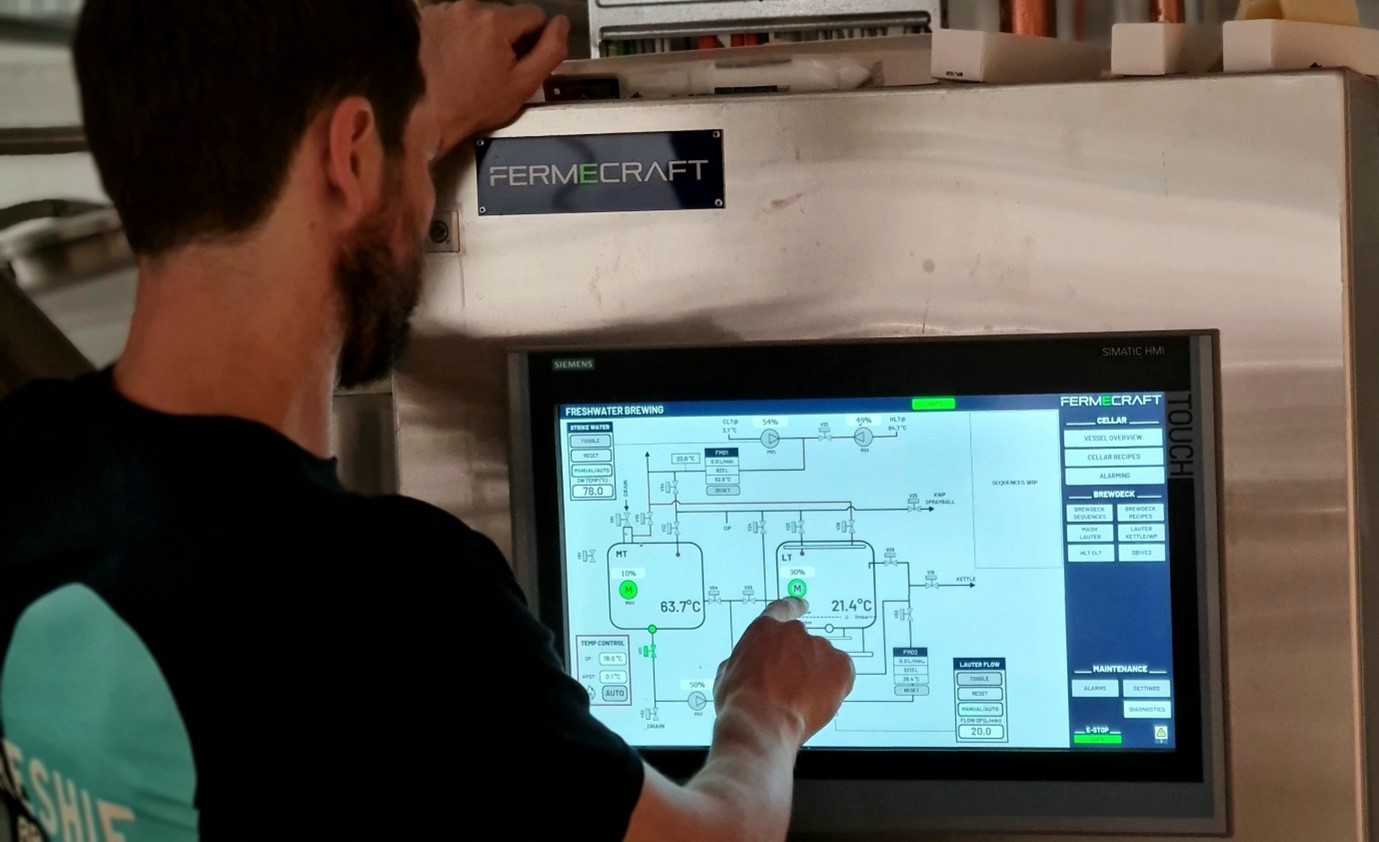

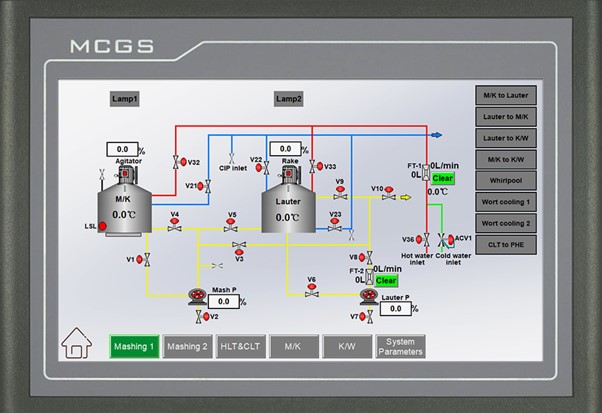

The brewer then controls much of what happens in his brewery by touching a screen, usually with a simplified representation of the brewery on the screen or PID (piping and instrumentation diagram) to open a valve, to start and stop a pump, set the speed of a pump or to set a temperature for a tank. This removes the need to run around the brewery so much and allows a good picture of what is happening in each tank – very useful if you’ve got multiple brews going at the same time.

These systems can also have limited ‘one-touch’ operation, they can open multiple valves, start a pump and zero a timer from one button. What they don’t generally have is the sensors and feedback loops to allow actual ‘control’ of a system.

Cost – 10-15% premium on manual.

Pro’s – less human energy utilised and simplified operation, less mistakes.

Con’s – Compressor or control system breakdown = no brewing.

Use – on systems 10hL and above.

Proxy Automation

This is a fancy way of saying it’s automated, but you need a brewer on hand; just in case things go a little awry, but also do the quantitative stuff like gravities, pH, sensory and make up for variations in materials and do hop, chemical and other additions. Be aware, that in-line analytical instrumentation is heinously expensive and rather unreliable – as are dosing systems and the like. A caring brewer with a pH meter and a drum of lactic acid is always going to be the go unless we’re talking super big breweries.

These kinds of automation, and there’s a few on the market with varying competency, are designed to manage macro-processes like mashing, sparging and run-offs. If you imagine pressing the ‘mash’ button, you can expect the system to open all the valves, start the pumps, put in a certain amount to water at the required temperature, mix the grain in and make sure the temperature is right before it starts a timer. It will then step mash according to your recipe and let you know when it’s done. You’ll probably then have to transfer the mash yourself into the lauter (although the system should have warmed it and filled the foundation water) and press another button to start the recirc and the run-off.

They will all differ but the primary goal here is for the system to have enough smarts to allow the brewer to leave the brewery alone with it’s PLC for an hour or so at a time and do something else without having to constantly check on the brewery. That said, you should also have remote access and control on these systems so you can keep an eye on things whilst you’re sitting in the corner catching up with your excise returns. Worth noting however that remote access and control can be a double-edged sword. Without myriad machine interlocks to make sure everything is closed, sealed and safe, things can go badly awry resulting in mashes and wort spread on the brewery floor rather safely in the mash tun or fermenter.

That said, the best of these systems (Fermecraft for example) can not only control your brewery, but can easily control just about anything else you might like. Your steam boiler, your refrigeration system, your solar panels and even your canning line. They can also gather huge amounts of data, chuck it into a database so you can nerd out on the success, or otherwise, of your brew.

Cost – 20-30% premium on manual.

Pro’s – good systems can save half your brewer’s time!

Con’s – bad systems can be a nightmare, creating more problems than solving them.

Use – 10hL to 100hL.

Full Automation

We’re very much getting into big brewery territory here and the cost of these systems skyrockets. The extra money goes less on computer power and programming (these are actually very similar to Proxy Auto) but more on dosing, analytical instrumentation, and safety interlocks. If you consider the simplicity of a brewer taking a pH reading and then adding a quick mentally calculated acid addition – doing this by computer requires all sorts of equipments and expensive measuring devices. Sensible if you’re doing 10 brews of 120hL a day, not so much if you’re doing one 10hL batch.

There’s also the safety aspects of full control – especially CIP where hot chemicals are being used. You need to make sure doors are closed, CO2 environments are purged, and pressures relieved if needed. All stuff a trained brewer does at the core of his job, expensive in terms of infrastructure to let the non-sentient computer take over.

Fully automated systems are not just for the brewhouse and tank farm nowadays. Pretty much everything in your brewery should be controlled or controllable – the big brewery suppliers have their own systems e.g. Krones, Rolec but there are very few after-market systems available or even affordable as a retro-fit.

Cost – lots.

Pro’s – highly automated for labour reduction and improved quality.

Con’s – very, VERY expensive and technical.

Use – 100hL +.

Brewtique’s Master Series Brewhouses incorporate the Fermecraft Automation Solution into the design and build stage of production ensuring a seamless interaction between brewing equipment and software. This has allowed us to provide fully automated breweries at a fraction of previous costs. Not only does the automation provide increased control and quality of beer, but it also manages the repetitive mundane tasks, leaving the brewer to focus on the more important tasks. Click here to find out more and get in touch.

This content is produced by Neal Cameron, Brewtique’s Technical Director.