Your Mates Brewing case study

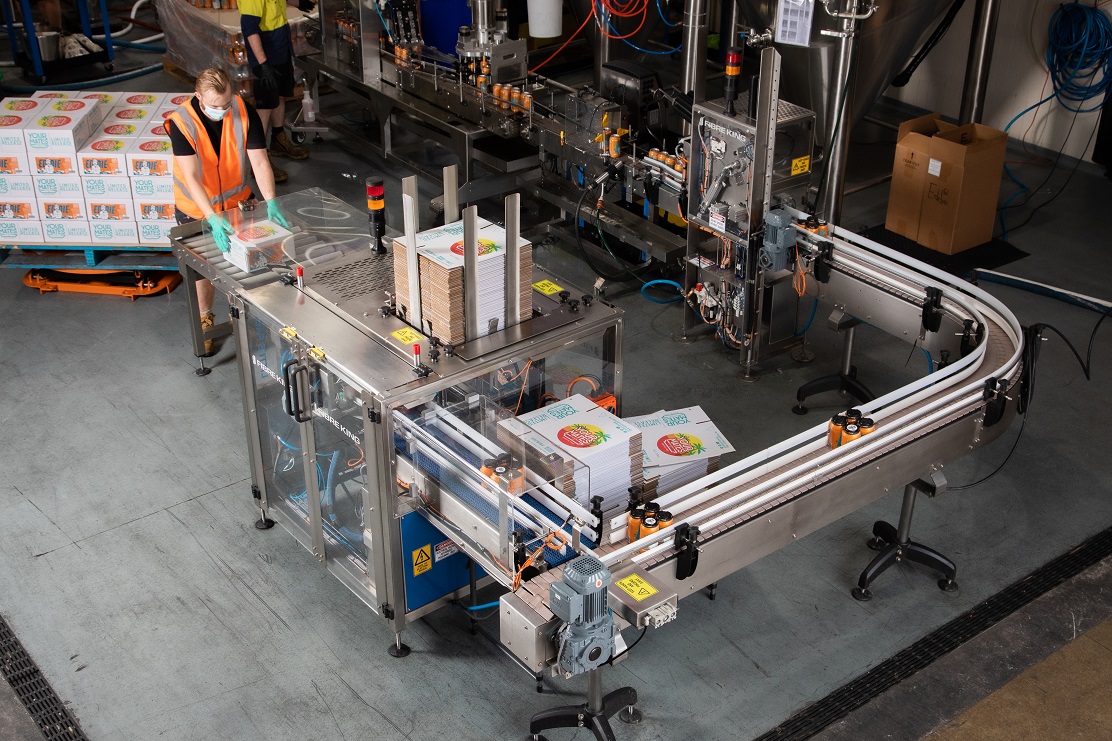

How Fibre King’s can carrier applicator and mini case packer helped this brewery remove their packaging bottleneck and gear up to meet demand.

The Challenge: Your Mates Brewing needed to move away from manual packaging processes to

increase production and reduce direct labour costs. Space was tight and the solution needed to be

compact.

The Solution: Fibre King delivered a compact end of line solution that included their new automatic

Can Carrier Applicator and their popular ‘Little Packer’ can case packer including all conveying

infeeds and outfeeds and working around the available space. The end solution was compact and

cost effective.

Services Rendered:

- Project management and seamless line integration with existing equipment

Equipment Used:

- Can carrier applicator

- Little Packer Case Packer

- Infeed and outfeed Conveyors

Your Mates brewing started in a garage in 2013 at the Sunshine Coast with 2 mates, an idea (some big balls) and a huge dream. With the help of friends, family and great mates the team were able to launch their signature beer ‘Larry’ in 2015. After Larry won 5th best beer in Australia in 2019 (a huge victory seeing as it was only available in South East Queensland at the time) the phones haven’t stopped ringing to get Larry around the country. Your Mates Brewing has doubled in size every year since they started and one of their biggest hurdles has been to be able to keep up with demand and automation was the next step. Your Mates Brewing is on track to brew 1 million litres of beer this year (2021) and to reach this ambitious target they had to address the bottle neck in their business that was their packaging line.

Your Mates had seen Fibre King equipment in similar sized breweries and heard great reviews of their equipment performance and naturally took the step to engage Fibre King and see what solution they could provide. Fibre King assessed their requirements including throughput volumes and available space and installed a Can Carrier Applicator, Little Packer and conveying system to work within the facility.

The automatic Can Carrier Applicator (CCA) collates cans and applies paktech clips at speeds of up to 30 picks per minute. This equates to 7200 cans per hour for 4 packs and 10800 cans per hour for 6 packs. The sealed cans move along a conveyor to the CCA where they are collated and clips are applied and are then conveyed to the ‘Little Packer’ Case Packer.

The Little Packer is the world’s smallest fully automated case erector, case loader and case sealer and operates up to 5 cases per minute.

“The Fibre King equipment hasn’t skipped a beat since we installed it.”

Says Christen McGarry – Head of production and director of Your Mates Brewing.

“Initially we had 5 staff running the canning line and since installing the Fibre King equipment we have been able to reduce the staff down to 2. This enables us to use those 5 staff over 2 shifts all while doubling the amount of beer packaged. The people running those shifts now have more time to focus on quality, the most important thing here at Your Mates Brewing,” adds Christen.

Your Mates has found that one of biggest perks of installing Fibre King equipment has been the local support they have received. After dealing with many internationally supplies in the past and the difficulty in getting support they have found this refreshing. The craft brewer is looking at building another facility in the near future to keep up with their keen customers and we look forward to watching their continued story.