Your Brewery Layout - Why it Needs to be Perfect

Anyone who has ever designed a brewery will tell you – getting the brewery layout right, from the beginning, is the key to success.

It is a delicate dance that takes real skill and experience.

The mission is to maximise the space to fit as much as you possibly can, while optimising the design for a smooth brewing process.

So how do you make sure it is just right?

Getting started on your brewery layout

At Bespoke Brewing Solutions, we have three key questions we ask our customers, in the early stages of the project.

- What is the size of your location?

- What are your monthly and annual production goals?

- What is your budget?

These answers will be our base, used to help us design a brewing system that meets your needs.

The next step is to calculate all the fun things! Like the recommended brewhouse and cellar vessel sizing, cost of equipment and floor space.

Tetris time – working the brewery equipment into the space

With all this information under our belts, we then move into the serious part.

A giant game of Tetris!

Our first step is to get a 2D CAD drawing of the space from either the designer/architect or landlord. This drawing is a really critical part of the process. If we are working off an inaccurate drawing, it can lead to serious – and costly – problems down the track.

We will identify the dimensions of each piece of equipment as well as both their dry and wet weights.

These dimensions are the foundation of the project. We really encourage they be shared with all the stakeholders involved in your project.

This includes all auxiliary equipment such as steam boilers, glycol chillers, water filters, packaging equipment, etc.

Underestimating weight can lead to foundation cracking. We also need to factor in trench drainage, which can take away the structural integrity of the slab if there’s too much weight and decrease height clearances if the need to add to the slab.

And here’s the really important part. The dimensions of the equipment and the location need to be exact. We’re not saying this to be pedantic! We are saying this because if they are off, by even one millimeter, we could have a serious problem on our hands.

One of the problems might be – we get to unloading day and a piece of equipment doesn’t fit into the space.

Nobody, and we mean nobody, wants this! This means the entire design is thrown off, and can lead to a domino effect of issues.

It’s drawing time!

Once we’ve worked out what equipment we need and how much we can fit into the space, we start drawing.

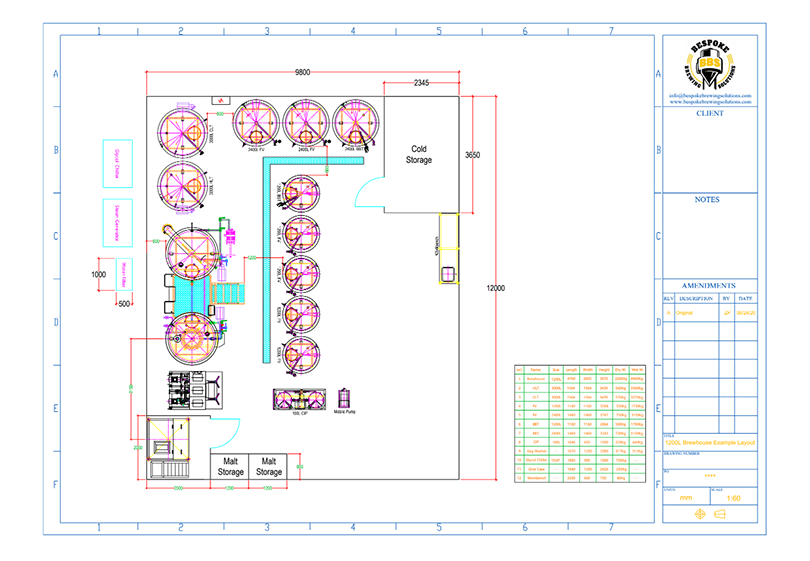

We create a series of diagrams that directly represent your brewery layout – exactly as it will appear in real life. We will live and die by these drawings, throughout the whole project.

When we design your brewery layout, we have the following things in mind:

- The process path – we design a layout which flows with the brewing process, to avoid unnecessary tasks and movements.

- Utilities – we make sure to take things like piping routing and power outlets into consideration in our brewery layout design.

- Room to expand – by planning for additional space ahead of time, you will save costs of having to redesign the equipment layout down the track. You can also plan on utility routing and include the initial build-out.

- General logic – you may be thinking, isn’t this a given? Well, you’d be surprised at some of the debacles we have seen over the years! We ask the important questions, like what would be the best location for the glycol inlets and outlets for a FV or BBT? We ensure there is space to get your pallet through, your brite tank is near the cold room and the lauder tun is close to the door so you can easily bring malt out and kegs in. Sometimes it’s the simple things that have a lasting effect.

Bespoke Brewing Solutions – A talented bunch!

Everyone involved in your project needs to be on the same page.

Between your brewer, designer/architect, structural engineer and contractor – there’s a lot of chefs in the kitchen.

We understand this. We are experts at managing these relationships – just ask our clients!

When you work with Bespoke Brewing Solutions, you have access to a consulting service, along with the highest quality equipment.

When you’ve been doing this for as long as we have, in over 12 different countries, we know what to look for. We know how things should flow and the best practice for your brewery layout.

We can preemptively identify where the roadblocks might pop up, so we can solve the issue before it arises.

If you’d like to work with us on your project, get in touch.