“Let’s be careful out there”

Those old enough to remember the ground-breaking cop drama Hill St Blues will recall the regular warning from Duty Sgt Phil Esterhaus as he sent his crew out on patrol. “Let’s be careful out there!” It was a poignant reminder that danger is an ever-present spectre for those working in certain professions and that those who let their attention lapse may pay the ultimate price.

Brewing beer, however, is an idyllic and carefree craft. It’s all about early morning mash-ins, arguing over the brewhouse iPod playlist and lazy afternoons spent taking fermentation temperatures and recording gravity. Some sampling from the conditioning tank fills in a few gaps in the work day and every brewer with a manual system dreads bottling day. About the only real danger to consider is forgetting to lift with the knees or hot-gluing a fingertip on the packaging line.

Or not.

You’re not learning anything new to hear that the brewhouse is every bit as dangerous as any other workplace. Recent events have shone a light on the need to be alert and prepared in the brewery and its related venues and have shown the high price that complacency commands. In this two-part article we’ll look at some of the more recent (and historical) hazards of the brewing life and then take a measured approach to mitigating risk and avoiding dangers in the brewhouse.

Most emergency service personnel will tell you that an ‘accident’ is indeed a very rare thing. Most ‘incidents’ are avoidable or have, at their cause, some degree of inattention to procedure or ignorance of the hazards inherent in the procedure. In reality, most incidents are not an isolated singular action but the culmination of several similarly singular actions that, combined, result in a failure of safety procedure. Everyone who has had a close-call or a near-miss (as OH & S manuals like to call them) recalls the tale with just a hint of ‘what might have been’ in their voice.

In September this year, Dan Dainton of Dainton Family Brewery caught his hand in a grain auger, breaking his finger in four places, tearing tendons and arteries in the process. Fortunately for him he was brewing at Cavalier Brewing and fellow tenant, Steve ‘Hendo’ Hederson from Brewcult arrived – but not before an agonising hour had elapsed. Hendo stayed with Dan until emergency services arrived and stayed with him on the way to hospital. Fortunately, Dan is well on the way to recovery.

Health and Safety reports into craft brewery accidents in the U.S. have identified the swift rise in the popularity of craft beer as a determining factor in the increase in workplace incidents. There is a belief that increasing demand has led to a slackening of adherence to safety protocols and in the rush to meet demand, worker safety is compromised.

“There were also nearly four times as many safety violations at craft breweries in recent years than at large breweries. And brewery experts say the safety oversight at smaller companies is worse than official statistics might suggest because injuries, even severe ones, often go unreported.”

Matt Stinchfield, a brewery safety consultant for insurance companies, said that as the industry scrambles to meet the exploding demand for craft beer, employee safety has sometimes been overlooked. “You have a few eager entrepreneurial spirits, and they don’t come with an industrial safety background,” he said. “There is still some growing up to do.”

While not related to the above report, Stone Brewing faced the tragedy of losing one of their own when a forklift accident claimed the life of Matt Courtright, a member of the brew team. On a recent visit to Australia, Stone founder Greg Koch told an assembled audience of the pain and desperate sense of loss this incident caused and those present could feel the deep effect this event had on Greg and the Stone family.

It is not just within the brewery walls that considerations of safety ends. An incident in which a young man was helping staff at a Newcastle Bowling Club to tap a keg which exploded, severing his arm, highlights the need to identify risks and to ensure correct procedures are understood and followed. Pressurised stainless steel containers can be just as dangerous empty as they are filled and should always be used with regulators and pressure relief valves. A follow up report can be found here.

Dr Brett J. Stubbs in a 2010 Brews News article identified a long list of brewery workers who have been killed or seriously injured in workplace incidents in Australia and New Zealand. Many of these were the results of oxygen starvation in fermenters and drownings or scaldings in hot liquor tanks and modern equipment and safety guidelines have mitigated many of these risks.

“Nowadays, when enclosed fermentation vessels are the norm, and on-the-job safety is paramount, fatalities like these are happily rare, so give thanks for such innovations when next you are enjoying a glass of your favourite fermented malt beverage. Spare a thought, too, for the brewery workers who have died doing their jobs, so that the rest of us may have our beer.”

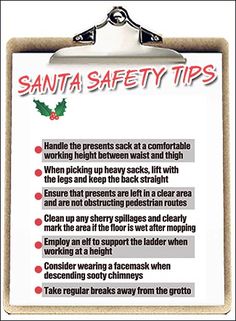

So as we head into the ‘silly season’ and the warmer weather sets in and production schedules ramp up let’s raise a glass to those who bring us summer refreshment and hope that each and every one of them stays safe to enjoy it with us.

Cheers.

In Part Two, we will look at some more cautionary tales as well as at some initiatives being implemented within the Australian craft beer scene.