From Colour Correction to Brand Differentiation

Author: Ruslan Hofmann, Sales Manager Europa bei PureMalt Products Ltd.

Contact: ruslan.hofmann@puremalt.com

Introduction

The use of roast malt beer or high gravity malt beers enable breweries to balance raw material derived swings in colour or to reduce the necessity to blend different brews. The handling of malt beer concentrates does allow inline dosing as well as batch addition, which not necessarily implements investment in highly accurate dosing systems. Furthermore, the use of malt beer concentrates offers fast product development and upscaling. With beer markets being under constant pressure throughout multiple crisis the possibility to create new or seasonal products at late stage can add just the flexibility that is needed without blocking capacity in the brewhouse or fermentation block.

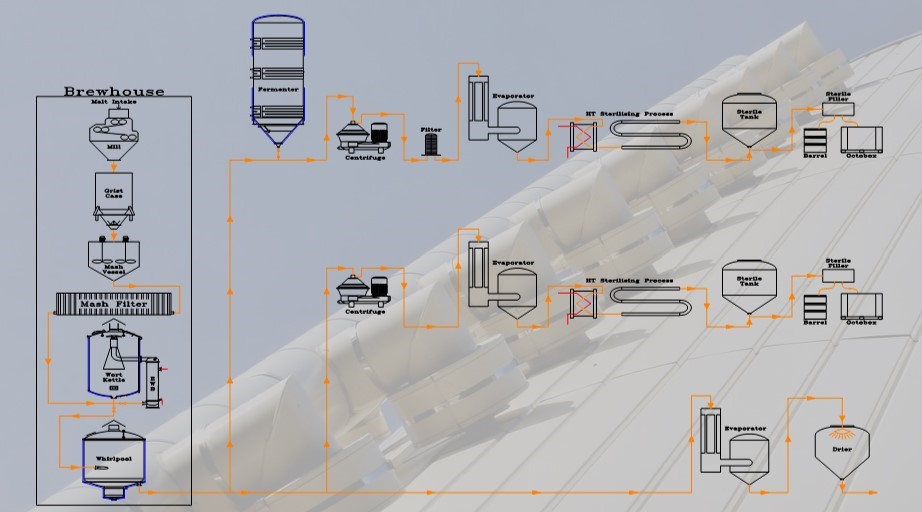

Production process of high gravity malt beers

Malt beer concentrates are traditionally brewed in the same way as regular beers, using the same ingredients water, malted barley, hops and bottom-fermenting yeast. In contrast to classic brews the malt bill contains mainly roast or specialty malts, in some cases up to 100 %.

Mashing, lautering and boiling use parameters like regular beers, although emphasis is put on extraction of colour and aroma compounds rather than sugars. With the high share of roast malt in the brewhouse the use of a mash filter is preferred to lauter tuns.

The addition of hops is usually very limited. The main purpose is to stabilise the precipitation of protein and to avoid intense foaming. Intense bitterness is most often not targeted to avoid unintentional increase of IBUs in the final beers.

After brewhouse handling the wort is fermented to a limited degree with bottom-fermenting yeast. A phase for clarification and filtration follows. Finally, the beer is concentrated to up to 65 % solids using a vacuum evaporation process which limits the thermal load and, thereby, avoids negative impact on taste.

High gravity malt beers are pasteurized in a final preservation step and filled aseptically or hot.

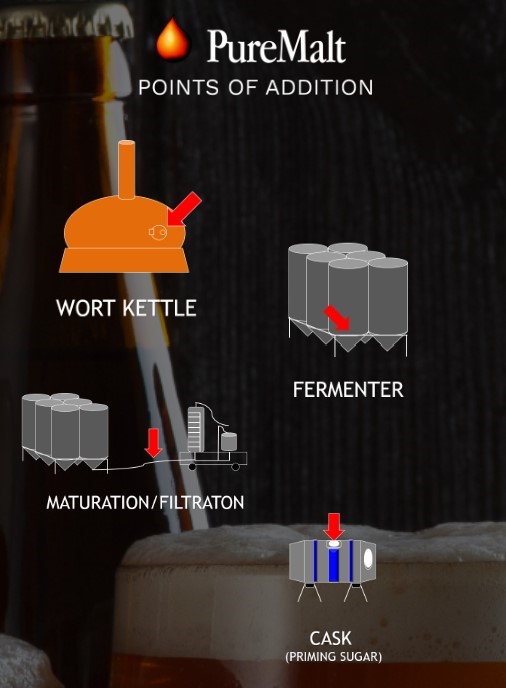

Dosing of malt beer concentrates in practice

Malt beer concentrates can be added at almost all stages of the brewing process. During wort boiling the product may be added into the wort kettle. The high degree of solubility does also allow addition to fermentation vessels during beer transfer. Another option is to dose the concentrate before or after filtration. In terms of a late-stage differentiation of main brews into the addition at filtration can be considered ideal.

The later the product is added the lower are process derived losses in colour or aroma. For a wort kettle addition up to 25 % of the added colour molecules may be lost during thermal processing and mainly during fermentation. Addition after main fermentation does reduce losses to 10 to 15 %, with the last step of filtration contributing about half of the losses.

Sizing and design of the dosing station enable inline correction with a subsequent colour measurement. Otherwise, a batch calculation may be done, and the addition rate adjusted to the total filter or transfer run. To ensure sufficient mixing a combination with elements to adjust gravity and carbon dioxide content is favourable.

Roast malt beers with low haze may be added even after filtration. Although the recommended products are low in turbidity the beer matrix is too complex to guarantee absence of any precipitation. Parameters like alcohol concentration, pH-value or calcium oxalate ratio have always to be factored in.

Another possible point of addition can be cask or bottle conditioning. Depending on the nature of the malt beer concentrate residual fermentable sugars may be present. Dosing priming sugars by addition of malt beer concentrates may, therefore, be microbiologically less susceptible alternative to using unfermented wort.

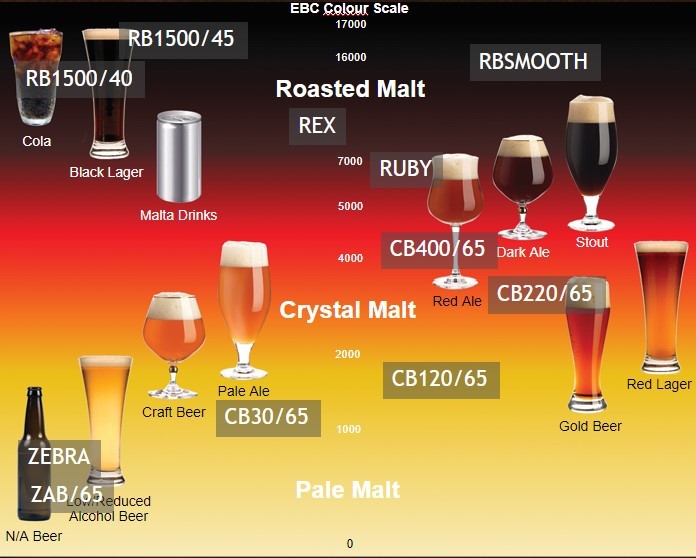

Colour correction or brand differentiation

The aims of using malt beer concentrates in breweries can be different. If colour levels in pale lagers or ales are to be corrected very small addition rates are sufficient. Depending on the colour level of the roast product 6 to 16 g/hL are enough to increase the final beer colour by 1 EBC.

To create a red or dark beer from a pale base beer up to 1 kg/hL may be necessary. Depending on the malt bill of the malt beer concentrate in question next to colour further changes in the beers matrix can arise. The characteristics of caramel or roast aroma may be intensified, body and mouthfeel are to be enhanced, or foam stability increased.

Malt beer concentrates and legal requirements

Roast malt beers or high gravity malt beers contain exactly the same ingredients as every other beer. Due to their fermented nature the product is a regular beer which is concentrated by evaporation. The resulting product is still beer, and the addition of malt beer concentrates is, strictly technical, a blending of two beers. The use of such malt beer concentrates is permitted even in Germany and corresponds with restrictions due the Reinheitsgebot (§ 17 Abs. 1 BierStDB). Of course, local legislation or personal preferences may limit the use of high gravity malt beers.

Advantages of using high gravity malt beers

The possibility to correct fluctuations in raw material quality by blending different brews is often limited to brands and breweries with high total output. For smaller breweries the use of mat beer concentrates may still be favourable. For example the handling and storage of specialty malts may be reduced. Carry over during milling or transport of roasted grist can be avoided. The extensive use of specialty malt in the malt bill is often accompanied by an immense drop in lautering performance. With the addition of malt beer concentrates to the wort kettle does improve lautering significantly. Capacity in brewhouse or fermentation block may be more efficiently utilized if the number of recipes is reduced, and several brands or brand extensions can be produced from a single batch of beer by a late stage differentiation.

The freedom to produce customized batch sizes up to 24 hours before filling does enable the brewer to react to market volatility in a highly flexible way. New ideas and brand concepts can be brought to life and to the customer without a time-consuming brewing and fermentation process. The product development starts with kitchen trials which do not involve more than a suitable scale and pipettes for correct dosing.

Applications beyond beer

Many breweries do bottle other products next to regular beers. These include alcohol free beers, soft drinks, or malt-based beverages. Roast malt beers are a natural colour for yellow, red brown to black and can be used as a clean-label alternative to caramel colour (E150). Thanks to the nature of producing the malt beer concentrates all products are free of any ethanol which makes them a perfect base for malt beverages or 0.0 alcohol beers. The same as for regular beer production applies for alcohol-free products when looking into brand differentiation and flexibility.

The residual sugars are all from a natural (starch) source and may be used as alternatives in soft drinks to increase sweet character, mouthfeel, and texture without adding to high carbohydrate and monosaccharides. Depending on local legislation sugar tax can be reduced.

Summary

For the production of specialty malt beer concentrates the same high-quality standards apply as for any other beer. Resulting products are defined by constantly monitored quality standards which allow clients to correct raw material derived fluctuation in their beers. Additionally, specialty malt beer concentrates are a source for efficient product development and late-stage brand differentiation. Any malt beer concentrate is by nature free of ethanol and can be used beyond regular beer production. E.g., for alcohol free beers, malt beverages or as clean-label colourant in energy drinks or colas.

Production process of specialty malt beer.

Possible addition points for specialty malt beer.

Examples and colour spectrum of specialty malts and resulting specialty malt beer.