Everything you need to know about steam heated brewing systems May 2021

The well managed use of high quality steam is a huge factor in producing a quality product – efficiently.

It is also a versatile addition to your brewhouse! Steam can be used in the heating, cleaning and pasteurisation processes.

Anyone who has worked with steam knows – a crucial proponent of saturated steam is that its temperature is directly related to its pressure.

Which means – quality brewery equipment is of utmost importance.

With that in mind, here are some things to take into account, if you are considering using a steam heated brewing system.

More bang for your buck?

Let’s put it right out there from the get go – a steam heated brewing system is not your cheapest option.

But hear us out.

Steam is:

- the most efficient and flexible method of heating

- used in the brewhouse for heating vessels

- used in keg washers for keg sterilization

- used in flash pasteurization systems

We always recommend a certified installer set everything up. They will also commission the system before it can be used (legally.)

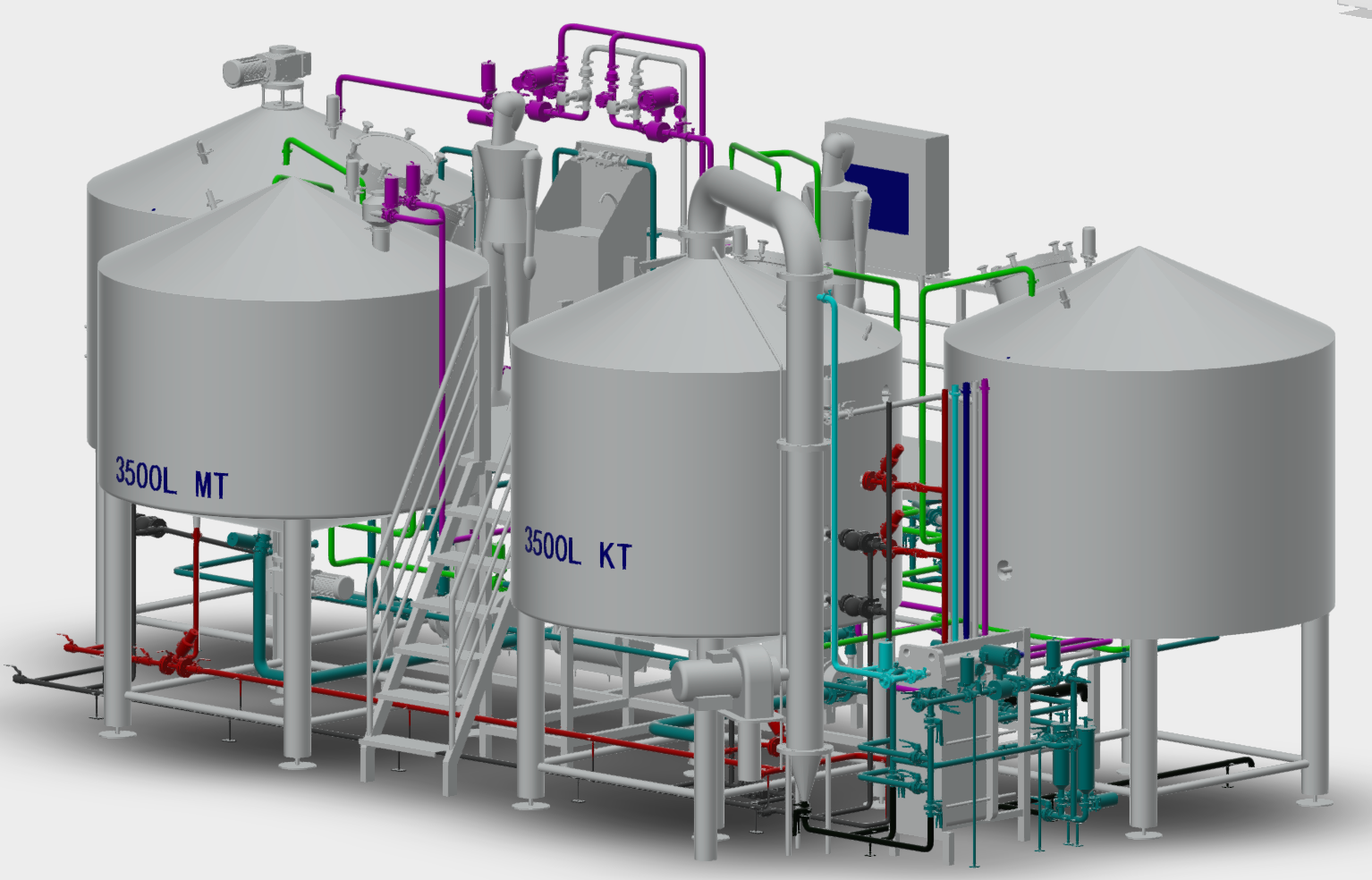

You will also need to complete a yearly inspection. In the picture of the 3D drawing below, you will see we have started fabricating steam piping and installing components on the steam lines.

At Bespoke Brewing Solutions, we ask our clients to review this with their steam system installer – as ultimately they will have to give final approval. We will also work with the local technicians to fabricate to their requirements.

As you can imagine, all these costs can add up. So it’s important to consider all these factors during your budgeting process.

Building a steam heated brewing system

When it comes to steam – different pieces of equipment will have different pressure requirements.

We encourage you to factor the max load of everything running – or at least think through what will be running simultaneously, to calculate the max load.

For boilers, you usually have two key heating methods – gas and electric.

While gas is cheaper, sometimes the location does not have gas available – so it’s got to be electric!

Electric boilers are power hungry – so make sure you have enough power coming in. It’s a good idea to go through the process and determine how much it will cost to run based on your kW per hr costs.

As a side note – some of our Oz clients are installing solar panels! This makes an electric boiler a great option. We recommend this for systems up to 1200L/10BBL.

Bespoke Pro Tip:

We have not yet sold a steam boiler to a more developed country, as the regulation on steam boilers can be strict, given they are pressure vessels.

So let’s say you’re procuring your system in China – and a steam boiler is included in the quote. We advise you to make sure it meets your local regulations.

Design and materials

We recommend steel (preferably stainless steel) for your steam piping.

Generally, the pipe is around 1” – but it also requires insulation and cladding. This will mean it will have a much larger diameter.

When it comes to connection types – the cheaper option is threaded connections. However – in our experience, flanges are better if you have the budget. This applies to the commentary on the steam pipework e.g. steam traps, solenoid valves and flow control valves.

You will also need to check the pressure required for the equipment. Our steam jackets are rated to 2 bar – but boilers usually run at a higher pressure.

You will also need a reducing station – and for bigger systems, you may need more than one! It can reduce flow as well.

Now to design. The key thing here is to ensure any equipment that uses steam is as close together as possible.

The reason for this is simple -piping can get to be expensive. Not only are you running pipe, but also insulation and potentially cladding.

Be aware of the water treatment you need for the internals of the boiler. Steam boilers require proper maintenance and monitoring to stay at peak performance. When you work with us, we’ll go through what needs to be done to keep it in top condition.

The bespoke difference

Our team has installed steam heated brewing systems in several countries. So we’d like to think that we have the experience to make sure nothing is overlooked.

A smooth installation means you get you brewing faster! It also means a more positive experience.

Our end goal is always to ensure your brewhouse is as efficient as possible – which we all know saves time and money.

If you’d like Bespoke Brewing Solutions to consult on installing your system – get in touch. We would love to work with you!

And if you’d like to read the previous blogs in this series, we have covered other utilities including liquor and electrical requirements – as well as design and layout.