Great leaps made in malt carbon reductions August 2023

Photo: Supplied Certified Sustainable

Sustainability consultant Dan Watters from Watters & Co looks at developments in barley growing that can help brewers boost sustainability.

Malt accounts for approximately a quarter of the brewing industry’s greenhouse gas emissions, and is often the single biggest contributor to a beer’s footprint.

Recent announcements by Rocky Ridge and Bintani have heralded the arrival of Certified Sustainable malt across the country with the same brewing specifications and flavour profile as conventional malt, but up to 80 per cent reduction in barley growing emissions.

While it’s currently priced 5 per cent higher than conventional malt, the resilience of sustainable grain to the vagaries of both climate and chemical prices could make it the cheaper alternative in the long run.

The potential for environmental wins social gains for farming communities are huge…making a compelling case for industry adoption.

The Issue

While sustainability benchmark data is hard to come by for the Australian brewing industry, figures from brewing giant Lion show malt contributes between 33-39 per cent of its carbon footprint.

North America’s New Belgium, producer of the first certified carbon-neutral beer claims a figure of 21 per cent when barley production and malting figures are combined.

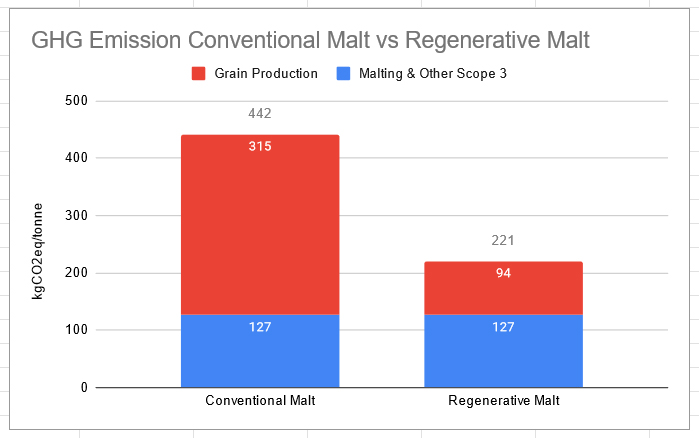

A study by UK-based maltsters Munton’s found that only 30 per cent (127kgCO2eq/kg) of malt emissions lie in the malting process, with the bulk being in the production of barley, specifically the use of nitrogen-based fertilisers and synthetic chemicals on crops, which leads to further problems.

Voyager craft malt Co-founder and Director Stu Whytcross likens the use of these chemicals to drug addiction.

“Put more nitrogen on a crop and you’ll get a higher yield. But you’re borrowing from the future; degrading the soil,” he said.

“You end up needing to add more and more chemicals to achieve the same results. It’s a vicious cycle.’’

The solution

The scale of the problem demands disruption to solve. Early experiments are proving there’s a relatively easy, inexpensive solution in the form of regenerative agriculture, achieving major reductions in emissions at the grain growing stage.

Miriam Neilson, Industry Development Manager from not-for-profit ESG audit body Certified Sustainable, says the single biggest reductions can be attributed to reduced synthetic fertiliser and crop protectants use due to healthier soils and better farm management practices resulting in less diesel use.

Farmers are turning to farm-made biological products to feed their soil microbes, such as seaweed, minerals and molasses.

Low tillage and the use of cover crops also contribute to healthier soils more resilient to climate variability.

Healthy soil. Photo: Supplied Certified Sustainable

Movements in the Market

The first batch of regeneratively grown barley left Voyager’s malt house for Stone & Wood 12 months ago. An independent audit of one of their growers by Certified Sustainable using the PICCC greenhouse accounting tool calculated the malt’s cradle-to-farm-gate greenhouse gas emissions of 60.9kg/T.

This is an 80 per cent reduction against a CSIRO/Grains Research & Development Corporation-derived Australian average of 315kg/T.

Voyager now has base and specialty malts made with CS grain in production.

Earlier this month, Rocky Ridge Brewery took their first delivery of 320 tonnes of Certified Sustainable base malt.

Grown near the brewery at Tolga Farm in the WA wheatbelt and single-batch malted at Joe White maltings in Perth, not only does it have low food miles, but it boasts a 63% reduction in barley production emissions.

Last week, 1000 tonnes of Joe White Certified Sustainable Signature Pils base malt with similar emissions reduction figures hit the market on the east coast through Bintani, who is keen to introduce Certified Sustainable specialty malts if there’s demand.

A multi-year average to account for season variability, different growing locations and conditions sees emissions reductions from regeneratively grown grain 70 per cent lower than conventional grain.

Even without emissions reduction on the malting side improvements on the growing side halves the total emissions from malt.

So what’s the catch? How does it perform?

Brewers are reporting they are pleased

“All the beer in FV [ferment] at the moment has been made with the Certified Sustainable base malt” Rocky Ridge head brewer Ross Terlick told Brews News.

“We’re very happy with the results. The COA [certificate of analysis] on the malt is like for like.”

Terlick said there’s been no change to the flavour profile of our core range beers.

“It processes exactly the same through the brewery,” he said.

“About the only change we’ve seen is a slightly higher limited attenuation so we’re getting a touch more body.”

Bintani’s CEO Phil Meddings says the malt hits all the same specs as conventional malt and it’s less than 5 per cent more expensive, despite the lower cost to the environment.

The stats and prices are the same at Voyager, but Whytcross notes the cost if farmers don’t move to regenerative methods.

“Synthetic inputs have been subject to huge price increases recently, and the more you add the more you degrade the soil, and the more you’ll need to add in future.”

Certified Sustainable’s Miriam Neilson is a former farmer and says regenerative methods “cuts out the rollercoaster ride” for growers, adding that building soil health “improves resilience to climatic issues like drought and floods” all of which are becoming more common.

“If everyone moved to sustainable malt we would see price fluctuations level out,” says Whytcross “and longer term they should be cheaper.”

Social Benefits

Even more important than the environmental gains is the positive mental health effects growing sustainably is having on farming communities.

Certified Sustainable’s Managing Director Ash Truscott audits farms not just on their environmental performance but also on social measures and says “it’s quite exciting to watch the journey of these farmers.”

MIriam Neilson agrees, adding farmers feel more in control.

“The management steps and the practices they’re putting in place put them in the best situation for whatever nature throws at them,” she said.

“The farmers feel like there’s benefits to what they’re doing, not just a whole bunch of really expensive inputs.”

Voyager’s Whytcross has witnessed the same effect.

“I don’t think you’ll find any farmer who wants to use synthetic fertilizer and damage their lands for future generations,” he said.

“This offers them the chance to get out of the vicious cycle.”

Low-hanging fruit

Given malt accounts for a quarter of all greenhouse gas emissions in the brewing industry, a complete switch to regeneratively-grown malt could cut total emissions by 12.5% overnight.

It represents one of the most cost-effective methods for substantial emissions reductions without the need for investment in new equipment or technology. And provides the added bonus of building healthier and more resilient soils and farming communities.

“It’s a really great opportunity for the industry to lead,” says Truscott.

“Not just by making the switch to sustainable grain, but brewers tell a story in a really great way with a can in your hand.”