A Little DePal Makes Big Change at Your Mates Brewery

Content published as an Announcement is produced by the business(es) named in the announcement and remains unedited by Brews News.

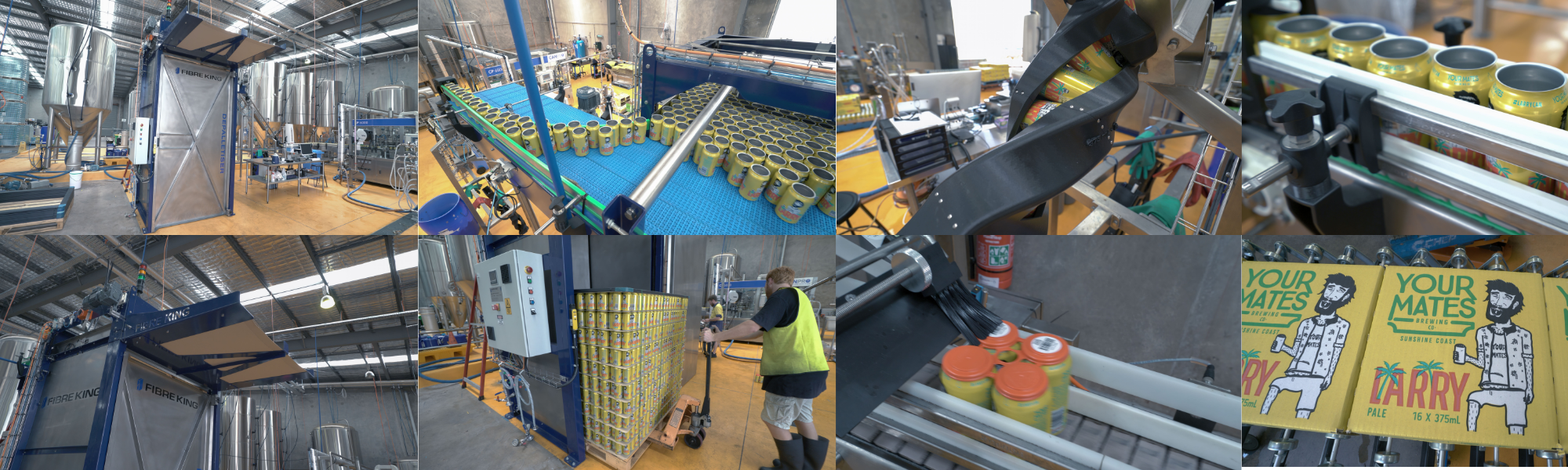

Part 2 of Your Mates production expansion includes more Fibre King equipment.

“How good is it to be back at Your Mates? Just two years after installing a little packer and CCA can carrier applicator, they’ve now tripled their throughput by replacing their filler and we’ve now added a small Automatic Depalletiser,” says James Windsor, CEO of Fibre King.

In 2021, Fibre King, the top end of line automation manufacturer in Australia, collaborated with Your Mates Brewery to address their packaging bottleneck. Fibre King’s solution involved automating Your Mates Brewery’s end of line clip application and case packing processes, resulting in increased efficiency and smoother operations. Now in 2023 Your Mates has added another bit of kit to the line and this time its Fibre Kings newly launched ‘Little DePal’.

“We’ve just added a little Depalletiser to the system and it has revolutionised the way that the canning line is operating and that the Canning line team is operating. Our team are able to now focus on the more important tasks including quality assurance and making sure that the cartons are all looking schmick before they get palletised instead of lifting cans into the filler,” says Christen McGarry, Head of Production and Director of Your Mates Brewing.

Specifically designed to cater to the needs of the craft brewery and beverage industry, the ‘Little’ Depalletiser is a compact, reliable depalletising solution that offers a high-quality alternative and meets Australian Safety Standards. The Little Depalletiser is engineered to automatically unload cans from pallets and feed them seamlessly into the production line, ensuring a smooth and uninterrupted process.

“The beauty of the Fibre King Little Depal is that it’s fully compliant to Australian standards and we haven’t compromised on any of the build quality that you’d see in the larger machines,” adds James.

“We’ve been running Fibre King equipment now for over two years and in that time, the equipment has not skipped a beat. I’d have no hesitation in recommending Fibre King for other breweries because an investment in Fibre King is an investment in the quality of the liquid that is going out to your consumers,” adds Christen.

Craft breweries looking to improve their production processes and gain a competitive edge in the market should strongly consider automating their end-of-line production processes. The benefits of automation are clear – increased efficiency, improved product quality, reduced labor costs, and enhanced workplace safety. By implementing automation solutions such as Fibre King’s ‘Little’ Depalletiser, craft breweries can streamline their operations and focus on the aspects of the business that matter most, such as recipe development, quality control, and customer service.

“At Fibre king, we really love building quality machinery that helps our clients get their products to market. It’s amazing to see the growth that your mates have gone through and it’s just really rewarding to be a key link in the production line that gets their products to market,” says James.

Fibre King’s compact range of equipment for craft brewers now includes; Casepacking, Palletising, De-Palletising, Can Carrier Applicator and conveying solutions. There is also a multipacker in the works to be released late 2023.

LITTLE DEPAL FEATURES

Heavy Duty Construction

Made out of stainless steel, our Depalletisers are designed for use in 24 hour per day production environments, for a serviceable life of 15 years.

Quick Changeover Times

Changeovers are quick and repeatable. Typical change over times of less than 2 minutes. Automatic adjustment between product heights.

Modular Design

Design is flexible to suit your production requirements. Fully enclosed hoist chamber to ensure that no product can fall.

Production Rate and Speed

120 cans / minute.

Colour Touch Screen

Full monitoring of machine status and diagnostics. Internet access enables our engineers to provide exceptional levels of remote support.

Robust Guarding

Electrically interlocked to AS4024.1 or equivalent International Standard. Give your staff the best protection and maximise uptime with quick access for setting up and clearing obstructions.

Options and Features

- Uniquely utilises pressureless singalising for smoother flow of cans with less damage.

- Layer sheet removal.

- Twist Rinser / Lowerator

- Multiple can sizes

- Anti Jam feature – the conveyor reverses if there is a jam to release the cans

- Air Ionizing Twist Rinsers include compressed air or vane pump blower units. Prefer water rinsing? We can integrate that too.

Don’t wait – take the first step towards automation today and reap the benefits of improved productivity and profitability. Call us on 1300 831 330